MIL-PRF-1/1427G

Dimensions

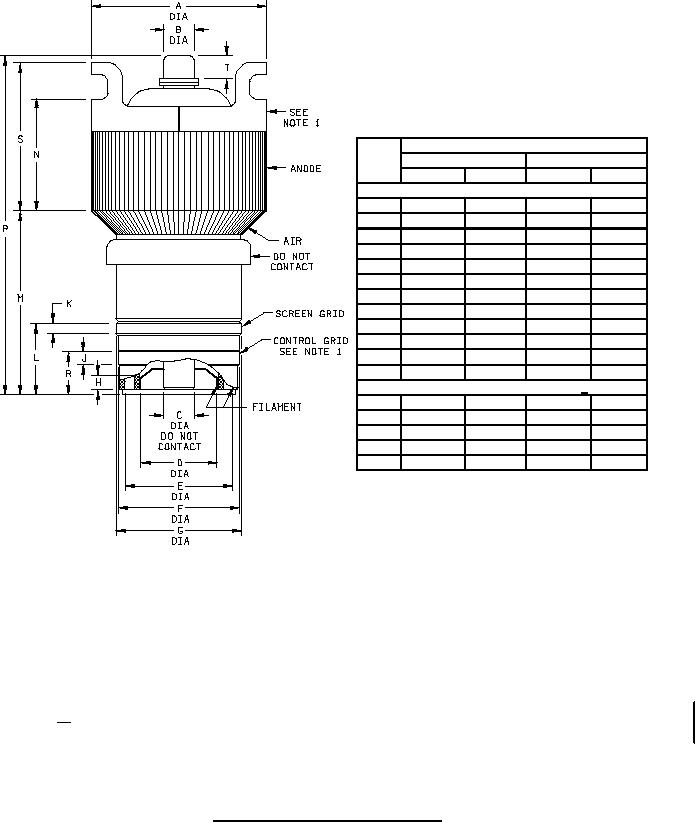

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 2

C

.600

.760

15.24

19.30

D

1.896

1.936

48.16

49.17

E

3.133

3.173

79.58

80.59

F

3.792

3.832

96.32

97.33

G

3.980

4.020

101.09

102.11

H

.188

---

4.78

---

J

.188

---

4.78

---

K

.188

---

4.78

---

L

1.764

1.826

44.81

46.38

P

8.625

9.125

219.08

231.78

R

.986

1.050

25.04

26.67

T

.375

---

9.53

---

Conformance inspection, part 3 3/

A

4.812

4.938

122.22

125.43

B

.855

.895

21.72

22.73

M

4.188

4.563

106.38

115.90

N

2.875

3.250

73.03

82.55

S

3.875

4.250

98.43

107.95

NOTES:

1. The total indicator reading (the sum of the positive and negative deflection shown by the indicator when measuring the

eccentricity of one surface with respect to another, with the reference axis established) of the screen grid and filament contact

surfaces shall not exceed .040 inch (1.02 mm) with respect to the control grid and anode contact surfaces when the latter

surfaces are rotated on rollers at the points indicated by the arrows. (Conformance inspection, part 2).

2. Letters H, J, K, N, and T also represent contact surfaces.

3. Dimensions shall be checked yearly. An accept on zero defect sampling plan shall be used, with sample of three tubes with an

acceptance number of zero. In the event of failure, the test will be made as a part of conformance inspection, part 2, acceptance

level 6.5 (see 11/). The yearly sampling plan may be reinstated after three consecutive samples have been accepted.

FIGURE 1. Outline drawing of electron tube type 8170W .

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business