MIL-PRF-1/1386F

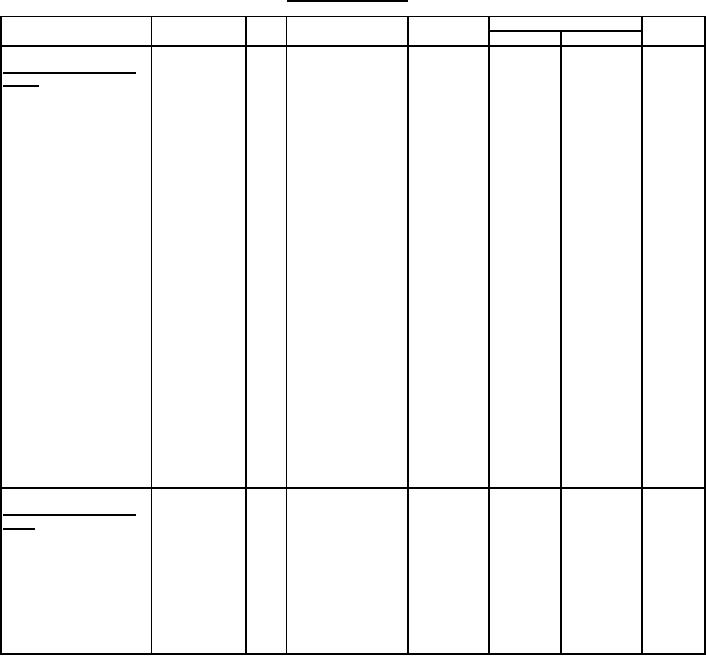

TABLE I. Testing and inspection. Continued

Limits

MIL-STD-1132

Requirement or Test

Notes

Conditions

Symbol

Unit

Method

Minimum

Maximum

Conformance inspection,

Part 2 Continued

---

Pin No. 4

---

5101

Side terminal and base

alinement

°C

11

+70

1026

-----

High-temperature

operation

-----

-----

----

-----

5101

------

Neck and base alignment

(electrostatic types)

Eb2 = 600 Vdc;

----

----

5216

----

Stray light emission

---

Eb3 = 3,400 Vdc

----

----

----

(conventional types)

----

cb

----

----

5221

360

Screen

----

Vdc

----

----

5246

40

Focusing voltage, zero-

Eb1

bins

μAdc

--

10

5251

----

Heater-cathode leackage

Ihk

current

----

1101

Secureness of base, cap,

----

----

----

or insert

----

----

----

1105

----

Permanence of marking

----

----

Conformance inspection,

Part 3

hrs

----

500

T

Group C;

Life test

Ib3 = 10 μAdc;

Eb2 = 575 Vdc;

Eb3 = 3,000 Vdc

Life-test end points:

Ib3 = 10μA

mm

0.75

----

----

----

5226

Line width "A"

Ib3 = 10μA

mm

0.80

----

----

----

5226

Line width "B'

ĆEc1

Ib3 = 10μA

Vdc

30

----

----

5223

Modulation

NOTES:

1.

All readings of beam current (Ib3) shall be in addition to the reading obtained for method 5201, anode No. 3 current. For

oscilloscope use, the mean potentials of 1D2 and 3D4 with respect to ground shall be zero.

2.

It is recommended that the deflecting electrode circuit resistance be approximately equal. Higher resistance values up to

5.0 megohms may be used for low-beam current operation.

With the beam cutoff, the post-accelecrator anode (A3) shall draw 15 μAdc maximum.

3.

4.

Spot adjusted for least astigmatism.

5.

With a 2.5-by 2-inch rectangular raster centered on the face of the tube, the raster edge shall not deviate form straight

parallel lines by more than 0.040 inch on the left and right edges nor by more than 0.0515 inch at the top and bottom.

4

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business