MIL-PRF-1/1373D

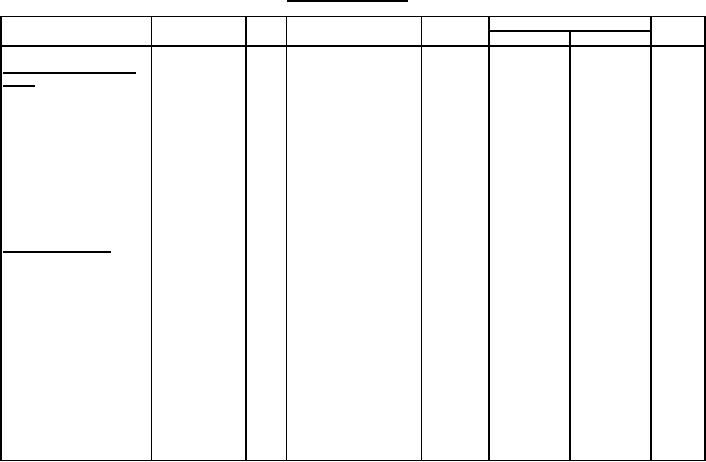

TABLE I. Testing and inspection. Continued

Limits

MIL-STD-1311

Inspection

Notes

Conditions

Symbol

Unit

Method

Minimum

Maximum

Conformance inspection,

Part 3

Life Test

-----

----

hrs

Group C:

t

500

Eb2 = 12,100 Vdc;

Ec2 = 770 Vdc;

Ib2 = 60 μAdc;

Eb1 at focus

Ib2 = 100 μAdc;

Life-test end points:

-----

-----

0.38

mm

Width

Ib2= 100 μAdc;

ĆEc1

Linewidth "A"

-----

5226

32

Vdc

Modulation

5223

Periodic-check tests

Pressure (implosion)

1141

Vibration

5111

2

mm

Width

μAdc

Electrode current

- 15

5201

+ 15

Ec1 = 0

Ic2

(grid No. 2)

Cathode illumination

5216

----

----

---

Direct-interelectrode

----

1331

8

pF

Cathode to all

Ck

capacitance

----

10

pF

Control grid to all

Cg1

Base material insulating

-----

1216

-----

-------

----

-----

quality

NOTES:

When Ec2 is greater than 330 Vdc, Rg1 shall not exceed 0.5 MegΩ. When Ec2 is less than 330 Vdc, Rg1 shall not

1.

Exceed 1.5 MegΩ.

2.

Cylinder shall be 4 inches (101.6 mm) long and 0.901 inch (22.89 mm) maximum inside diameter.

3.

The screen characteristics shall be measured with a constant beam energy of 0.24 watt defocused to a spot

approximately 0.25 cm in diameter.

The test conditions shall be Eb2 = 10,000 Vdc.

Ib2 = 24 μ Adc.

The screen characteristics shall be cB5 450 cB minimum,

G5:1 = 4 minimum

4.

This test to be performed at the conclusion of the holding period.

5.

The two sets of neck support referenced in method 5101 shall be spaced 1.125 inches (28.58 mm) and 3.25 inches

(82.55 mm) below reference plane.

6.

Tube type 7AQP33 has been added to this tube specification sheet.

7.

An accept on zero defect sampling plan (see MIL-PRF-1, table III) shall be used for conformance inspection, part 1..

3

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business