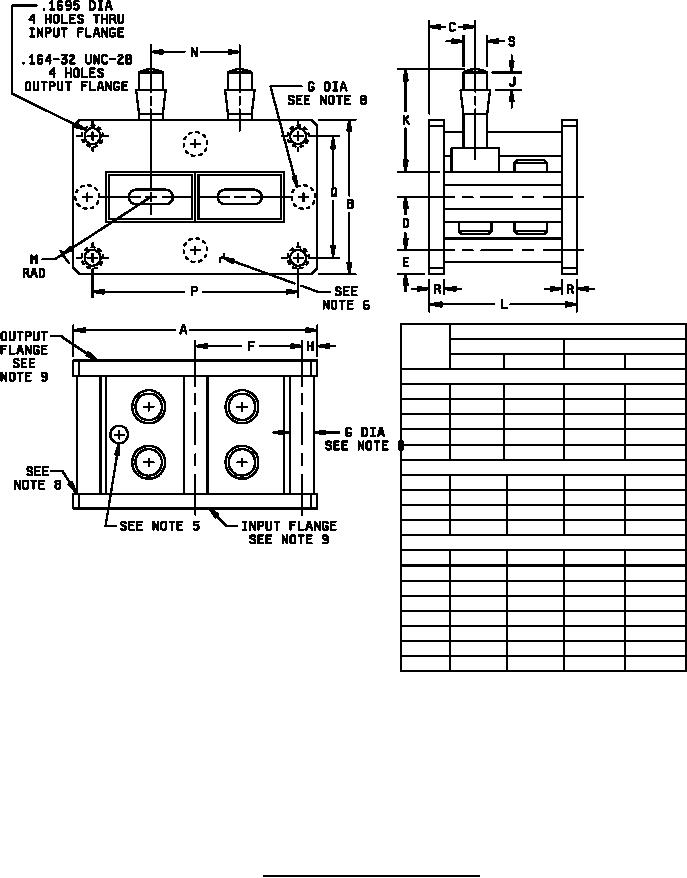

MIL-PRF-1/1254E

Dimensions

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 1

J

.200

---

5.08

---

K

1.000

1.125

25.40

28.58

L

1.545

1.565

39.24

39.75

M

1.109

1.140

28.17

28.96

N

.920

.980

23.37

24.89

Conformance inspection, part 2

P

2.165

2.175

54.99

55.25

Q

1.276

1.284

32.40

32.61

R

.156

---

3.96

---

S

.245

.255

6.22

6.48

Qualification

A

2.560

2.590

65.02

65.79

B

1.610

1.640

40.83

41.66

C

.375

---

9.53

---

D

.546

.578

13.87

14.68

E

.234

.265

5.94

6.73

F

1.109

1.140

28.17

28.96

G

.234

.265

5.94

6.73

NOTES:

H

.140

.171

3.56

4.34

1. Metric equivalents (to the nearest 0.01 mm) are given for general

information only and are based upon 1 inch = 25.4 mm.

2. The rectangle formed by the four mounting holes on each flange shall be centered on the flange face within .031 inch

(0.79 mm).

3. Silver plate 100 MSI, or equivalent.

4. Rhodium flash over silver plate optional.

5. Exhaust tube shall not extend beyond flange and shall not block mounting holes.

6. Input flange of tube shall be flat within .004 inch (0.10 mm).

7. Finish: black paladin primer followed by optical black baking enamel, or approved equivalent, to all outside surfaces

except contacting surfaces of flanges, holes, and threads of flanges and electrode insulators and caps.

8. Four .250 inch (6.35 mm) diameter rods brazed or welded to flanges in eight places on tube flanges spaced as shown on

figure 1. Rods for mechanical support only.

9. Mark "input" or "output" on edge of each flange as appropriate.

FIGURE 1. Outline drawing of electron tube type 7381.

5

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business