MIL-PRF-1/1120G

TABLE I. Testing and inspection - Continued.

20/

Measured in socket in accordance with Drawing 158-JAN.

21/

Grid-anode resonance:

Test in cavity in accordance with Drawing 278-JAN. Cavity shall resonate at 1.354 GHz ± 2.0 MHz

with tuning slug in accordance with Drawing 277-JAN at TA = 25°C ± 5°C.

Grid-cathode resonance: Test in cavity in accordance with Drawing 283-JAN. Cavity shall resonate at 1.719 GHz ± 2.0

MHz with tuning slug in accordance with Drawing 277-JAN at TA = 25°C ± 5°C.

W hen plotted on graphs of resonant frequency versus grid-anode capacitance and resonant frequency versus grid-cathode

capacitance, the tube under test shall be represented by a point within a parallelogram whose four corners are located by the

following points:

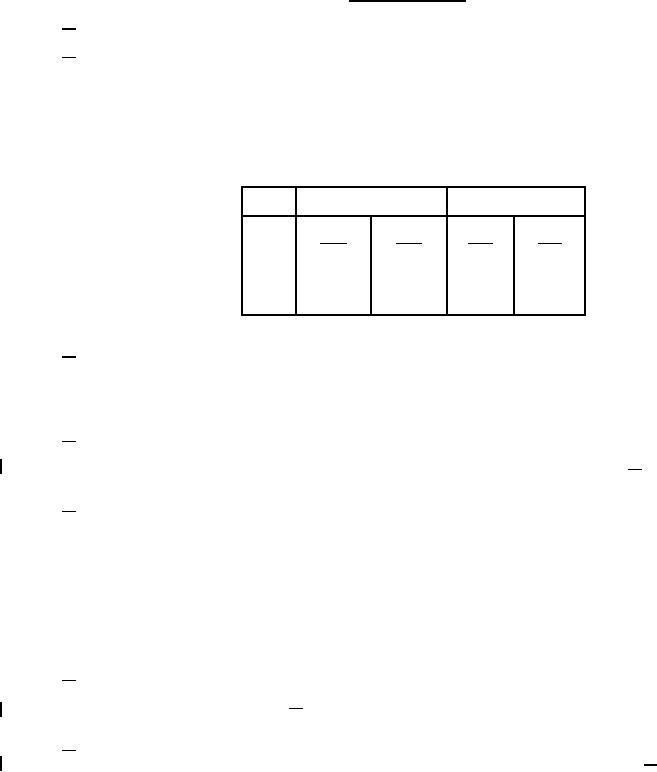

Points

Capacitance (pF)

Frequency (GHz)

C-gp

C-gk

F-gp

F-gk

1

1.95

5.6

1.955

1.784

2

1.95

5.6

1.985

1.814

3

2.15

7.0

1.900

1.751

4

2.15

7.0

1.930

1.781

22/

Test shall be made in cavity in accordance with Drawing 281-JAN. Calibrate the circuit by adjusting the cavity until the frequency

of resonance is 2.0 GHz ± 5 MHz at room temperature, with a tube which meets the resonance test requirements. In the grid-

distortion test, the frequency shall first be measured with Ef = 6.0 volts, then the grid dissipation increased to 2 watts with

Eb = -150 V dc. The change in frequency shall be not greater than the limit specified herein. Cooling air at room temperature may

be used.

23/

Voltage shall be 60 Hz ac applied between anode and grid. No other voltages shall be applied. There shall be no evidence of

failure as indicated by an arc-over. Perform test on 10 tubes selected from the first production lot of each year. If more than one

tube fails, the test shall become a part of conformance inspection, part 2, with acceptance level 6.5 (see 30/). After three

consecutive successful submissions, the test shall revert to a 10-tube annual test. This is not a destructive test.

24/

The tube shall be mounted in socket in accordance with Drawing 276-JAN and vibrated with simple harmonic motion. The peak

acceleration over the frequency range shall be within ±20 percent of the reference acceleration at 100 Hz. The frequency shall

vary from 55 to 500 Hz and return to 55 Hz with approximately logarithmic progression and shall require 4 minutes minimum, 6

minutes maximum to traverse the range. Each tube shall be vibrated for 30 minutes in each axis X and Z, except that if the

cumulative result of tests on 50 or more tubes of a construction show that more than 75 percent of the tubes have higher output

voltages in one axis, subsequent measurements need to be taken only in the axis giving the higher reading. The voltages specified

herein shall be applied to the tube during vibration. The value of the alternating voltage, Ep, produced across the resistor, Rp, as a

result of vibration shall be measured with a suitable device. This device shall have an appropriate voltage range, shall have the

ability to measure, with an error of less than 10 percent, the rms value of a sine wave of voltage at all frequencies from 20 to 20,000

Hz. The value of the vibrational output, Ep, shall not exceed the limit specified herein at any point in the sweep-frequency range

during the last complete cycle of cycling vibration.

25/

Test 10 tubes selected at random from the first production lot of each calendar year and approximately every 90 days during the

year. If more than one tube fails to pass the specified end points, the failed test shall become a part of conformance inspection,

part 2, with acceptance level 6.5 (see 30/), on all lots in process. After three consecutive successful submissions, the test shall

revert to a 10-tube quarterly test. This is a nondestructive test, except in case of failure.

26/

Test four tubes selected at random from the first production lot of each year. If one or more tubes fail to pass the specified end

points, the failed test shall become a part of conformance inspection, part 2, with acceptance level 6.5 (see 30/) , on all lots in

process. After three consecutive successful submissions, the test shall revert to a 4-tube annual test. This is a destructive test.

6

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business