MIL-PRF-1/1099H

Dimensions

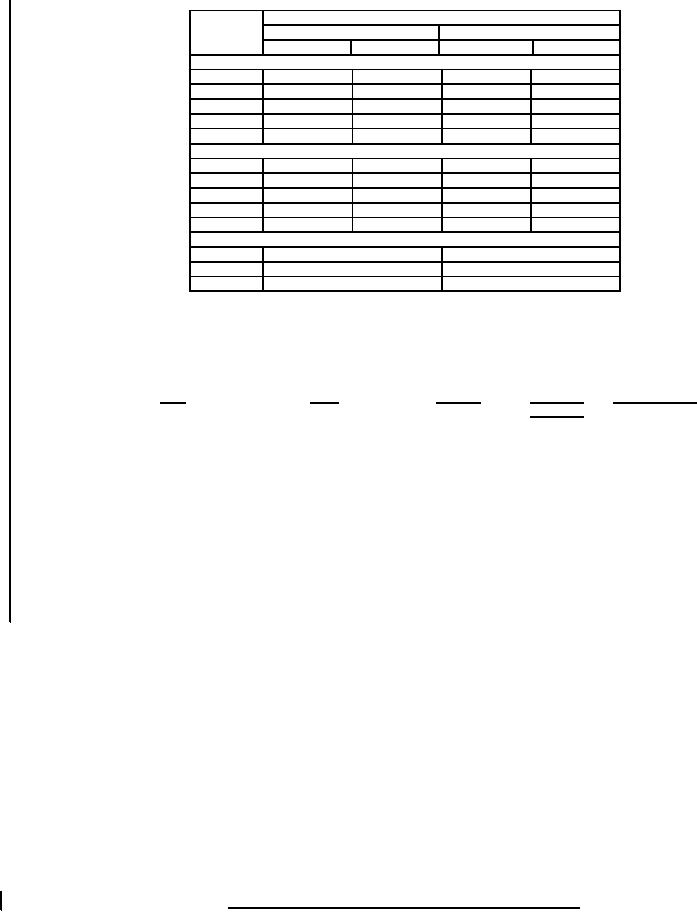

Ltr

Inches

Millimeters

Min

Max

Min

Max

Conformance inspection, part 2

A

11.530

12.281

292.87

311.93

B

---

3.312

---

84.12

C

8.343

9.469

211.90

240.50

R

2.662

2.682

67.61

68.12

T

89°60'

90°40'

89°60'

90°40'

Conformance inspection, part 3 (see note j)

D

7.500

8.500

190.50

215.90

E

5.938

6.062

150.83

153.97

S

.309

.315

7.85

8.00

U

.559

.573

14.20

14.55

V

.500

---

12.70

---

Reference dimensions

G

.063

1.60

2

W

14 AW G

2.5 mm

2

X

10 AW G

6.0 mm

NOTES:

a. Mounting flange is electrically isolated.

b. Dimension D is measured from bottom of flange to center of lead lug hole.

c. Leads shall be flexible. Leads shall be identified as follows:

Lead

Lug (see note h)

Color

Sleeving

Reference

dimension

G (grid)

Green

H-A-1 (see note d)

W

SAE-AS25036-108

H (heater)

Yellow

H-A-1 or H-8-1

W

SAE-AS25036-157

HR (heater) (see note f)

Yellow with black sleeve

H-A-1 or H-8-1

SAE-AS25036-157

W

HR (reservoir) (see note f)

Red with yellow sleeve

H-A-1 or H-8-1

SAE-AS25036-108

W

R (reservoir)

Red

H-A-1 or H-8-1

SAE-AS25036-108

W

K (cathode)

Black

SAE-AS25036-157

H-A-1 or H-8-1

X

d.

As specified in MIL-I-3190.

e.

Reservoir voltage shall be inscribed once above each mounting hole on aluminum base shell.

f.

Heater lead HR internally connected to reservoir lead HR.

g.

Cathode heater connection to this lead.

h.

Lugs shall be permanently identified with symbols as follows:

G (grid), K (cathode), H (heater), R (reservoir), and HR (heater-reservoir).

i.

Holes shall be inspected for orientation by using the base gauge outlined in figure 4.

FIGURE 5. Outline drawing of electron tube type 5948C (alternate glass version) - Continued.

10

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business