MIL-PRF-1/1048D

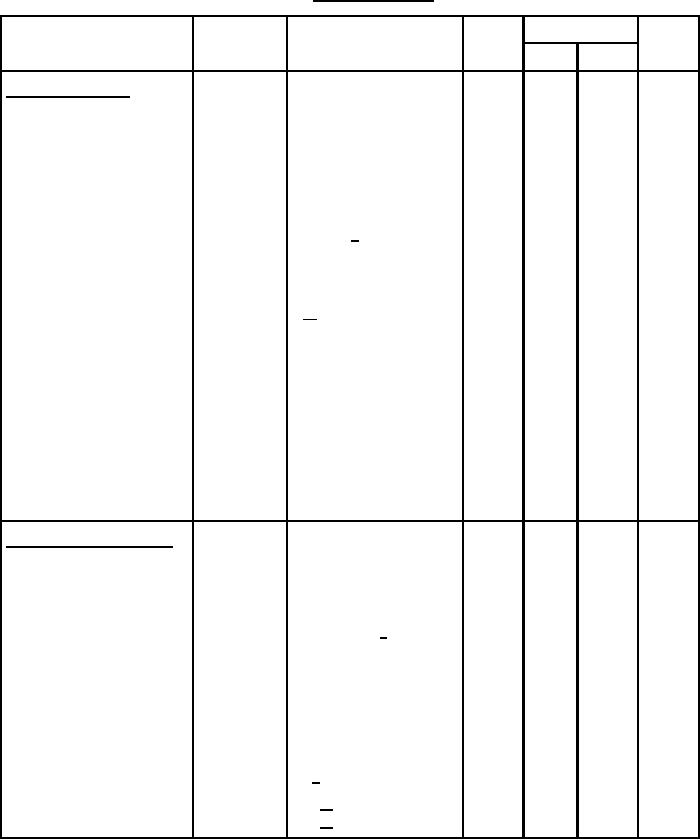

TABLE I. Testing and inspection.

Inspection

Method

Conditions

Symbol

Unit

Limits

MIL-STD-1311

Min

Max

Qualification inspection

Base material insulating quality

1216

---

---

---

---

Neck and bulb alignment

5101

Dia

---

3.31

inch

(electrostatic types)

Face lift

5101

---

---

---

---

Cathode illumination

5216

---

---

---

---

Barometric pressure, reduced

1002

87 mmHg 6/

---

---

---

---

Pressure (implosion)

1141

---

---

---

---

Vibration

5111

Width

---

1

mm

Direct-interelectrode

1331

12/

k to all

capacitance

Ck

---

4.6

pF

g1 to all

Cg1

---

4.0

pF

D1 to D2

C1D2

---

2.0

pF

D3 to D4

C3D4

---

1.4

pF

D1 to all

CD1

---

5.0

pF

D2 to all

CD2

---

5.0

pF

D3 to all

CD3

---

4.1

pF

D4 to all

CD4

---

4.1

pF

Deflection-factor uniformity

5248

1D2

---

---

2

%

3D4

---

---

3

%

-6

Interaction factor

5250

---

---

inch/V dc

14 x 10

Magnetization

5256

---

---

---

---

Conformance inspection, part 1

Voltage breakdown

5201

---

---

---

---

Voltage breakdown

5201

---

---

---

---

(electrostatic types)

lb3 = 50 μA dc 5/

Gas "cross"

5206

---

---

---

---

Ib3 = 25 μA dc

ΔEc1

Modulation

5223

---

35

V dc

Spot position

5231

---

---

15

mm

(electrostatic deflection)

Spot displacement (leakage)

5231

Displ

---

10

mm

Grid cutoff voltage

5241

Eco

-45

-75

V dc

Tracking

---

9/

---

---

1.5

%

Useful scan

---

---

---

4

inch

1D2 10/

---

---

4

inch

3D4 10/

See footnotes at end of table.

2

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business