MIL-DTL-24251/6E

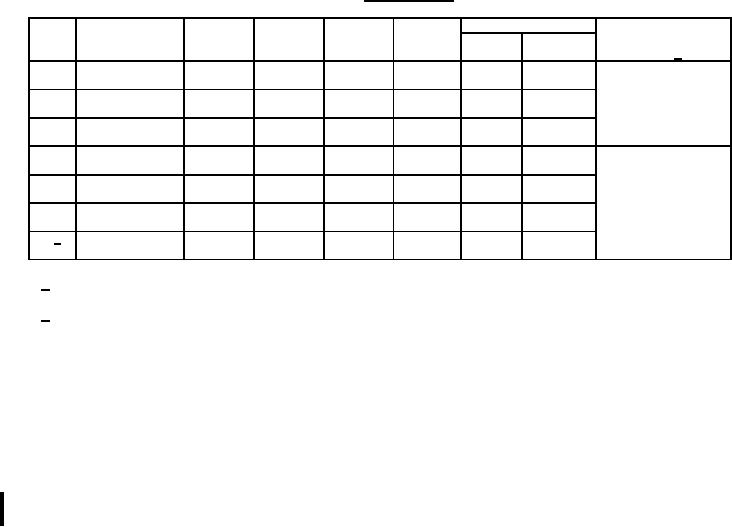

TABLE 1. Characteristics.

Dash

Heat dissipation

A

B

C dia

Weight

Tube envelope

Tube

±.015

no.

temp. reduction

-.062

grams

socket

Style

Length

in °C (minimum)

(1.57)

Max

max

ref

2/

nom

(0.38)

1

25

1.500

1.625

.875

11.0

T-5 1/2

1.125

(38.10)

(41.28)

(22.23)

(28.58)

MIL-DTL-12883/2

2

40

2.000

2.125

.875

15.0

T-5 1/2

1.500

(50.80)

(53.98)

(22.23)

(38.10)

3

45

2.500

2.625

.875

19.0

T-5 1/2

2.000

(63.50)

(66.68)

(22.23)

(50.80)

4

25

1.500

1.625

1.000

12.0

T-6 1/2

1.125

MIL-DTL-12883/3

(38.10)

(41.28)

(25.40)

(28.58)

5

55

2.000

2.125

1.000

16.0

T-6 1/2

1.562

(50.80)

(53.98)

(25.40)

(39.67)

6

45

2.500

2.625

1.000

20.0

T-6 1/2

2.000

(63.50)

(66.68)

(25.40)

(50.80)

7 1/

45

2.750

2.875

1.000

22.0

T-6 1/2

2.812

(69.85)

(73.03)

(25.40)

(71.42)

1/ This shield is for use with noval tubes which are longer than usual tubes.

2/ Not recommended for new design.

REQUIREMENTS:

The shield, locking mechanism, liner, and other parts shall be designed to meet the requirements in MIL-DTL-

24251, and to fit the tube envelope and tube socket specified in table I.

Dimensions and configuration: See figure 1 and table I. No special retainer (base) or adapter will be permitted.

Material:

Spring (when used): Beryllium copper, ASTM-B194, ASTM-B196/B196M and ASTM-B197/B197M.

Shell: Aluminum alloy, SAE-AMS-QQ-A-250 (aerospace and unspecified applications), or ASTM-B209 (non-

aerospace applications).

Liner: Beryllium copper, ASTM-B194.

Finish:

Spring (when used): Black cadmium plate, SAE-AMS-QQ-P-416, class 1, type II.

Shell: Black anodize, type II in accordance with MIL-A-8625, black matte in accordance with MIL-DTL-5541,

optional finish: Henderlube or equal.

Liner: Black cadmium plate, SAE-AMS-QQ-P-416, class 3, type II, optional finish: Henderlube or equal.

Construction: The spring shall be held in place by friction or by mechanical means if the maximum diameter is

smaller than the inside diameter of the shield. The tension shall be such as will insure maximum compression

of .125 inch (3.18 mm) over seated tube. The force required to compress spring to .375 inch (9.53 mm) shall be

within 1.5 to 2.5 pounds. Spirals shall not touch each other. The end of the coil spring shall not contact the

electron tube envelope.

Installation force shall not exceed 20 pounds.

Engaging torque: 20 inch-pounds maximum.

2